Machine foundation is designed so that the dynamic forces of the machine are safely transmitted to the soil through the foundation.

The machine foundation should be designed to limit the amplitude displacement and not disturb the people who work near the machine. When the design of machine foundations does not satisfy the acceptable value of the dynamic response (such as the maximum amplitude of displacement), the stabilization of soil under the foundation should be used to decrease the amplitude of displacement.

Design Criteria for Machine Foundations

- 1. It should be safe from a bearing capacity failure under static as well as dynamic loads.

- The dynamic response of the machine-foundation-soil system must be within the prescribed limits under operation conditions.

- The natural frequency of the machine-foundation-soil system should not coincide with the operating frequency of the machine i.e. There should be no resonance.

- The C.G. of the machine should be in the same vertical line as the C.G. of the foundation system.

Categories of Machine Foundation:

Every Machine is different and may have a different effect such as rotation, impact etc.

1. Reciprocating Machines that produce periodic unbalanced force. Their operating frequency is 600 RPM. The unbalanced force is assumed to vary sinusoidally.

2. Impact Machines that produce impact loads. The dynamic load reaches a high value within a short duration and then die out quickly.

3. Rotary Machines are a high-speed machine.

Types of machine foundations:

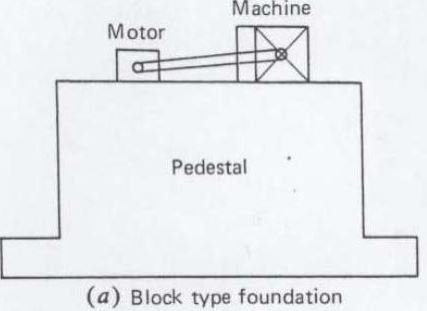

Block foundation

It consists of a heavy block of concrete resting directly on soil or supported on piles or a pedestal resting on a footing. The heavyweight of the foundation results in a smaller natural frequency of the system.

A block foundation is easy to construct and have high bending and torsional stiffness. It is commonly used for compressor and reciprocating machines.

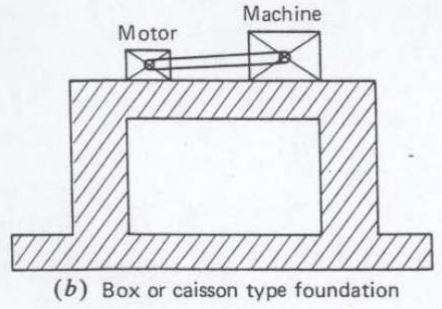

Box or Caisson foundation:

When a relatively lighter foundation is desired, the box or passion type of foundation may be provided. It consists of a hollow concrete block that can be used as an operational space and supports the machine on its top.

Wall-type foundation:

Wall type foundation is adopted for very high-speed machines and Steam turbines that require large operational space below for connecting pipes and additional equipment.

This type of foundation consists of a system of walls- columns and beam-slabs. In this type of foundation, elements are relatively flexible. It can be constructed by either RCC or steel frames. The steel frames are easy to construct but their behaviour under dynamic loading is not as good as that of an RCC frame.

Plate Foundation

The machine is placed on the plate made of concrete resting directly on soil or supported on piles. The plate foundation has high static stiffness and is easy to construct.

Dynamic response of machine foundation

Effect of shape, size, and moment of inertia:

Increase in footing mass or moment of inertia leads to a decrease in resonant frequency and effective damping but increase in amplitude at resonance. The shape of the foundation does not have a great influence on the response of footings with equal areas. In case of very long and narrow footing, it is a common practice to idealize shape to that of an infinitely long strip.

Effect of finite depth of stratum over bedrock.:

In the case of vertical and horizontal modes of vibration great influence of bedrock has been observed. A decrease in depth of soil stratum leads to decrease in radiation damping and an increase in the resonant frequency of the foundation soil system. Rocking and torsional mode of vibration is influenced by the soil close to the surface.

Effect of embedment:

Embedment increases the stiffness of the soil foundation system. This leads to a decrease in amplitude and increase in resonant frequency. Effect of embedment is more in two rotational modes of vibration than translational modes

In the design of machine foundations, the first numerical limits of failure need to be calculated. Second, the relation between applied loads and quantities which are significant in design. Third, To evaluate the significant quantities and what are the errors involved. Finally, after the inaccuracies involved in evaluating these quantities are determined, what sort of factor of safety do we apply in the design process is to be calculated.

Also Read:

Pingback: Your Machine Foundation Guide: From Concept to Completion - Venwiz