Geosynthetics are natural or polymeric material used with soil, rock or any other related building materials.

Geosynthetics have entirely changed the way civil engineering, especially geotechnical engineering, is practised. Geosynthetics gives Innovative solutions to solve severe problems economically and expediently.

Geosynthetics enables the use of local materials, i.e., sustainable solutions.

Many manufacturing companies around the world produce a comprehensive range of Geosynthetics and other related products in Civil engineering and construction systems.

In India, naturally occurring geosynthetic is mainly produced along the coastal region of South India.

Primary Function of Geosynthetics

B – Barrier (e.g., All hydraulic application, dam, canal, etc.)

D – Drainage (e.g., Retaining Wall, Sports field)

E – Erosion Control (e.g., Geosynthetic mat fence slope)

F – Filtration (e.g., Highway drain system)

R – Reinforcement (e.g., Slope Stability)

S – Separation (e.g., Railroad bases, paved road & unpaved road)

Major Applications of Geosynthetics

- Reinforced soil walls/Slopes protection for approaches to Bridges, Flyovers, Road Over Bridges, Underpasses, Highways/ Pavement roads, Railways, and Airport runways.

- Land reclamation (Ground improvement)

- River training, Coastal erosion and Scour control

- Landscaping, Buildings, Water Harvesting, Basement Water Proofing

- Drainage, Separation, Filtration, Erosion Control, and Revegetation

- Waste Water Treatment

- Rockfall protection/control

- Sports fields and Golf courses

- Land reclamation and Remediation,

- Landslide Prevention and Many More

Green highways and streets construction

Building environmentally and economically sustainable transportation infrastructure highways.

Recycled materials in the pavement can reduce:

- Global warming potential by 32%

- Energy consumption by 28%

- Water consumption by 29%

- Hazard waste generation by 25%

Geosynthetics reduce the carbon footprint contributed by the infrastructure development while minimizing the use of natural resources. When used with the local sub graded soil, it significantly reduces the carbon footprint by 30%.

Advantages of Geosynthetics

- Smaller construction footprints (e.g., less land disturbance)

- Geosynthetics are lighter than earthen materials so it requires fewer truckloads for transportations. (e.g.,150 earthen materials truckloads = 1 truckload of geosynthetic rolls)

- Greater reuse of on-site materials with geosynthetics vs. trucking in special fills.

- It reduces maintenance costs and increases life.

- It has excellent flexibility, stress-strain behaviour, filtration characteristics.

- It is widely available, welded together, and doesn’t form by-products.

- It saves substantial costs as well as the time over alternative solutions. The quality can be controlled as manufactured in a factory.

- It has generic specifications and easy to install.

Disadvantages of Geosynthetics

- Natural geosynthetics are biodegradable; hence their life is short. Thus can’t be used for the structures of long life.

- The exposed life of geosynthetics, being polymeric, is less than unexposed as when soil is backfilled.

- For long term performance of geosynthetics, they are chemically ultraviolet stabilized, which is harmful.

- Clogging of geosynthetics is challenging for specific soil types or unusual situations. For example, loose soils, fine cohesionless silts soil are troublesome.

- Carrying, Handling, Storage, and Installation must be assured by careful quality control and quality assurance.

Categories of Geosynthetics

Geosynthetics occur in various configurations. They may be either natural or artificially produced.

Some of them are listed below:

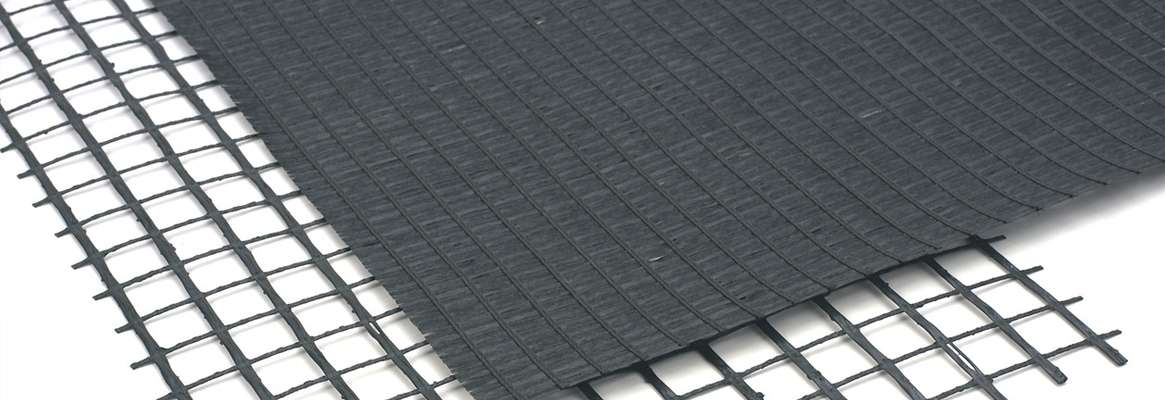

- Geotextiles (Knitted, Woven, Non-Woven)

- Geogrids (Bonded, Knitted, Extruded, Woven)

- Geonets

- Geocells

- Geomembranes (Bituminous, Elastomeric)

- Pre-fabricated vertical drains (PVD)

- Geocomposites & Geo-others

Generally, geosynthetics products occur in polymeric form. As there are various types of polymers, depending on the type of polymer selected, the properties of geosynthetics also vary. Their quality can be controlled during manufacturing processes.

It is best to build the sustainable value-added economic, environmental infrastructures in which transference plays a crucial role. The proper use of materials can reduce hazardous waste generation, greenhouse gas emission, water, and energy consumption, global warming, and the cost of infrastructures and increase service life.