Textile Reinforced Concrete (TRC) is an innovative technology in concrete filed in which the steel reinforcement is replaced by textile reinforcement. These fibres are mesh-like structures made up of glass, polypropene, jute, carbon etc.

Textile Reinforced Concrete is commonly used in lightweight structures such as precast members, shells, road screens, and faded elements. The prime quality of Textile Reinforced Concrete possess over other RC concrete is its resistance to corrosion and chemical (acid or alkaline) attacks.

In addition, the implementation of Textile Reinforcement can improve the compressive strength, flexural strength, and impact strength of concrete. Being it is very less in weight the load on the structure can considerably reduce by using textile-reinforced concrete.

Also Read: Polymer Concrete

Different types of Textile fibres

Alkali resistant glass (AR Glass): These are derived from organic non-metallic raw materials. These raw materials go to the melting process in 12500C to 1350 0C to form molten glass and fabrication of molten glass is done by wet-spinning process.

Basalt: Basalt is extracted from volcanic rock. The manufacturing process of basalt fibre is similar to glass fibres. It is cost-effective and good tensile strength.

Carbon: Carbon fibre is produced from the element polyacrylonitrile an organic polymer resin. Carbon has good tensile strength and low heating expansion. But it is not economic and has bad adhesion to concrete.

Polypropylene Fibre: Polypropylene and nylon fibres are found good in increase impact strength. They possess high tensile strength, but due to low elasticity and higher elongation do not give good flexural strength.

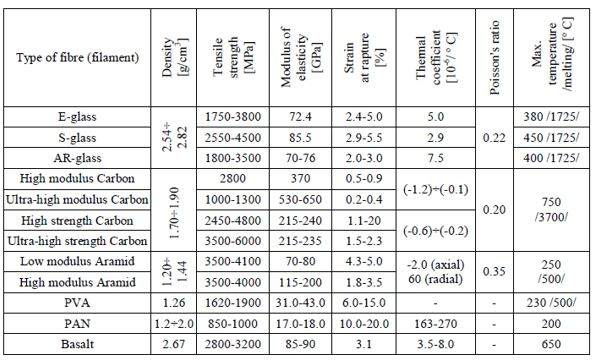

Detailed information regarding Textile fibre types given on the table below. These are some of the textile fibres commonly used. There are verities of textiles fibres are available.

Mechanical properties of Textile reinforced concrete

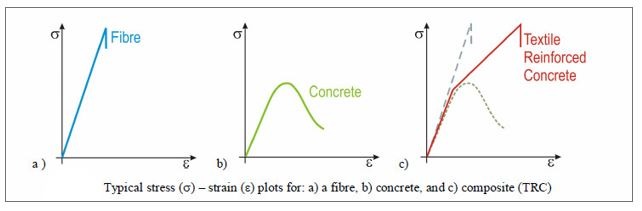

The graph below shows the stress-strain relations of TRC compared to other concretes. TRC posses a linear plastic behaviour with hardening. Another structural advantage of TRC is the multidirectional quality which is the possibility of aligns yarn in the direction of expected tensile stress. The carbon textile reinforcement undergoes brittle failure at the ultimate limit strain.

Applications of Textile Reinforced Concrete (TRC)

Textile reinforced concrete can be used for repairing of existing RC structures or strengthening old buildings (historic buildings) etc. Once the existing plaster is removed, the surface of the existing concrete is roughened also other defects were repaired. After that textile reinforcement if placed with subsequent layers of concrete sprayed. This is the procedure for repairing old buildings.

Textile materials like Kevlar or jute or glass fibres are used in the construction of pillars, bridges, and road guards etc. to limit sudden jerks, vibrations and torsions. As said earlier the textile reinforced concrete used for the construction of lightweight structures and pre-cast materials because in that way a lot of weight gets reduced.

Advantages of Textile Reinforced concrete

- Since steel is excluded in TRC there is no chance for corrosion and any types of chemical attacks. Also, a significant amount of load can be reduced in the structure.

- Amount of concrete can be reduced in TRC method compared to normal RC concrete because in TRC reinforcement cover is not needed and also TRC provide good bond force compared to steel bars in normal concrete.

- It is very effective in creating lightweight structures and pre-cast elements.

- Textile reinforced concrete has good tensile strength also increases the load-carrying capacity of reinforced concrete.

- The crack control system in textile-reinforced concrete is much better than traditional steel-reinforced concrete. When textile-reinforced concrete cracks multiple small fissures forms between 50 and 100 nanometres. In some cases, the crack can self-heal because 50 nanometres almost as impermeable as non-cracked concrete

Disadvantages of Textile Reinforced Concrete

- Not much economical compared to Steel Reinforced concrete

- Sensitive to moisture and UV radiation

- Lack of fire resistance

- Sensitive to cross pressure

The introduction of Textile Reinforced concrete created wide changes in construction technology. TRC’s qualities of corrosion and acid attack prevention are creating more durability to the buildings and also possess good strength characteristics.

Considering all these factors, Textile Reinforce concrete is essential to implement in future construction practices. While we go through current construction statistics need of strengthening and repairing of buildings is essential and will increases dramatically in the near future. So the application of TRC in this purpose is very needful. The application of TRC in bridge, pillar, other retaining structures should explore more and it became a future construction method.