Construction site safety is required to save the lives of workers employed at the construction site.

Construction is the second-largest activity, next to agriculture in India, which employs illiterate/semi-literate migrant workers intensively. The construction sector is dynamic in nature and highly accident-prone. A small accident at a construction site may affect the entire workflow and planning of the project and it costs a lot (both in time and money).

Considering the Indian construction sector, 80% of construction sites can be considered unsafe and deaths are approximately 20 times more comparing to the UK. An average of 38 fatal accidents is happening in India every day. These data’s clearly states that the safety measurements in our construction sector need to develop better. The main objective of construction safety is to provide a safe working condition and reduce work-related accidents.

The workers’ dedication and hard work really make the building design into reality. So prime importance should be given for ensuring the workers’ safety in the construction site. Unfortunately, there are not enough safety measures are implementing on construction sites.

There are different hazardous tasks in construction such as working on height, using different types of tools, working on excavation and effects of noise, dust etc. The common causalities happening in construction sites are falling from height, electrocution, injuries from tools, stuck between objects etc. Losing worker due to the injuries or accident causes significant disruption to the work and damage work morality and ethics, also a loss to their families.

Core elements of the Construction Site Safety Programme

Good management leadership: Management should show their commitment to identifying and eliminating hazards and implementing safety measurement to ensuring the well-being of workers. Safety first must be the priority of management in construction work. For that provide good safety gears to workers and frequently check the safety of workers at every level.

Workers attitude: All workers should have a clear picture of work they are doing and make sure that they are taking the right safety measures. Workers should report any possibilities of hazards and safety threats to management.

Hazard identification and Safety inspection: Frequent inspections and checking should carry out on the workplace to find out possible hazards risks. Identification of safety risks is a crucial part of the safety planning program. For that follow frequently happened hazards or injuries to workers and find out root causes to the incident.

Hazard prevention: In order to create a safe and healthy working environment, make a hazard prevention plan or safety guide and make sure the right PPE is using by workers. Always make sure that workers are following the safety plan and their involvement in adopting precautions.

Training: Training workers and engineers is very important to prevent a hazardous situation. Each and every employee should get the proper training to work safely, how to use safety equipment properly and how to tackle a hazardous situation. The training should include understating a hazard, how to eliminate, report and control it.

Periodic evaluation: Safety and health measures implemented on sites should periodically be evaluated and checked whether the employees are following it correctly and also to find out any faults happening in safety plans. Also, periodic inspection and monitoring help to improve the safety and health plans.

Basic Construction Site Safety Tips

- Always wear protective equipment

- Passages should be kept clear all the time.

- The materials and tools should be sorted and pile them up safely. The stacks should not be

too high. - Make sure that floor openings are fenced or covered.

- The workplace should have sufficient ventilation and lighting.

- The workers should be vigilant all the time and watch out for moving cranes, hooks or other lifting equipment.

- Do not allow the electric cables to come into contact with water.

- Do not drink or take drugs while working.

- The workers should be familiar with the location.

- Every worker should know how to operate the fire-fighting equipment.

Construction Site Safety Measures

Most accidents at the construction site can be prevented by adopting proper working procedures and taking simple protection measures such as:

Fall Protection:

In all construction sites, one of the most leading causes of accidents is due to fall from heights. Employers should provide a fall protection system on working surfaces which are unprotected and above 6ft from the lower level. Fall protection includes safety nets, rail guards, safety ropes. Workers should aware of using these safety measures.

Eye and Face Protection:

Proper face masks and eye protection goggles should be provided to workers from the impact of flying metal particles, dust, chemical liquids etc. Eye protection goggles are important from the impact of light while doing welding works, chipping, grinding, and drilling. Eye and face protection gears should meet the specified qualities and standard recommended by safety authorities.

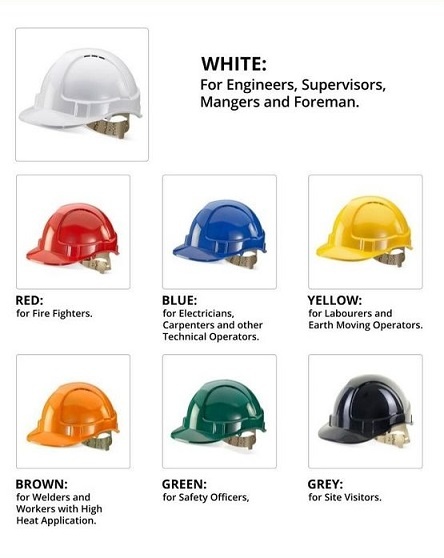

Head Protection Hats:

Protection hats are very common in construction sites which are used to protect the head from potential strikes of objects while working. These hats are made of hard plastic and the suspension of 30mm from shell to wearer’s head protects from the impact of a collision.

Safety During excavation:

Excavation and trenching works are the most dangerous jobs in the construction industry. Workers should wear safety hats and ensure the working environment is safe from falls of objects, electrocution and other heavy equipment accidents. For excavations more than five feet, proper access should provide in and out by ramp, ladder or stairways. Also, a professional safety engineer should check out the safety measures insides the trench every day before work starts.

Scaffold Safety:

Scaffolds are temporary platforms for construction works. Scaffolds should strong enough to carry temporary loads and free from unwanted movement. Proper erection of scaffolds is important in preventing hazards. A knowledgeable person should present while building, moving or dismantling scaffoldings. Also, workers should be trained enough to operate temporary lifts for construction purposes. There many possible hazards associated with the lifts such as platform tip-off, structural failures, electric shock etc. Always check the working conditions of lifts before work starts

Other personal protective equipment likes boots, reflective safety vests, gloves for hand safety, high visibility clothes, and ear protection devices should also be used well for better safety in construction.

Efforts in India

Government of India has set up the National Safety Council (NSC) which develops and carries the movement on Safety, Health and Environment (SHE) at the national level.

It organises various activities such as specialized training courses, seminars, conferences, workshops. NSC also conduct consultancy services such as safety audits, hazard evaluation & risk assessment and designing and facilitate organizations in celebrating various campaigns such as Safety Day, Fire Service Week, etc.

In India, 4th March is celebrated as National Safety Day/Week every year, during which various campaigns are organized to promote Safety, Health and Environment (SHE) movement in the country.

The BIS (Bureau of Indian Standards) have done intensive researches and studies to publish many SP and IS codes, to bring standardization acting as guidelines for construction, manufacturing, processing etc.

Also Read:

Civil Construction works are also hazardous. Hazards are related to Digging, Trench, Cranes etc.