Building material is any substance used for construction purposes, like materials for building a house . Innovative building materials are the need of the hour.

Clay, wood, cement, lime, concrete, aggregates, bricks, glass, metals etc. are the common materials used in construction. The choice of the material is based on their cost-effectiveness for building projects.

Innovation is a broad concept that includes improvements in processes, products, or services. It involves incorporating new ideas that generate changes that help solve the needs of an institute and so increase its competitiveness. Innovation is something new, something more effective than the existing technology.

Need for Innovative Building Materials

Nowadays, many new emerging innovative materials are being invented, and lots of new materials are being in research. New innovative thinking and new invention are necessary to save lots of our valuable time and energy.

The application of innovation to the construction industry is not straightforward. Every construction project is different, which means construction companies must adapt their processes and resources to suit each project. The anticipated revolution in construction is gaining momentum. Researchers of various institutes are taking technology to the next level with development in concrete and different other construction materials.

Innovative innovative materials

Translucent Cement

Normally you wouldn’t expect a dark grey lump of cement to be translucent but the new material produced shows otherwise. Translucent concrete may be a concrete based artefact with light-transmissive properties thanks to embedded light optical elements. It is usually made of optical fibre.

According to the concretes manufacturers, the optical fibres structure only 4 percent of the mixture. The light-transmitting property makes them appear open, fresh, and spacious. This cement can be used in place of glass, fibreglass any such transparent material with the strength of cement.

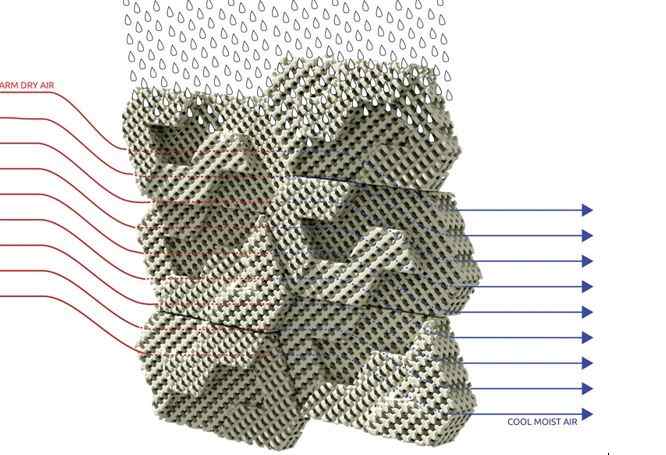

Hydro ceramic

A recent project at Barcelona’s IAAC architecture school researchers developed a prototype material – a product they call hydrodynamics. It can reduce the internal temperature by as much as 5°C compared to the outside level. The cooling effect of hydro ceramic comes from the presence of hydrogel in its structure which absorbs water, up to 500 times its weight.

It has an innovative cooling system despite being cheaper and cost-effective. It could reduce air-conditioning bills by 28 %.

Pollution Absorbing Bricks

Developed by assistant professor Carmen. The Breathe bricks suck in pollutants in the air and releases filtered air. The innovative material is meant to be a part of a building’s standard ventilation.

The centre may be a cyclone filtration system that separates out the heavy air particles from the air and collects them during a removable hopper. By performing structure tests, it had been proven that the system can filter 30% fine particle pollutants and 100% coarse particles like dust.

The primary advantage of this material is its property of Air filtering which prevents the microorganisms from passing through, thus prevent the diseases to enter. Part of its application being Ventilation systems and such.

Self Healing Concrete

Dr. Shlangen at Delft University has created a block of concrete that repairs itself when exposed to heat. He demonstrated this technology by tearing apart two pieces of concrete, placing them together, and then heating them up to allow them to meld together.

Researchers made use of a type of bacteria that is frequently found near the region of active volcanoes. They have created a bio concrete that heals itself using this bacteria, just like the way our body heals injured bone through mineralization. Researchers have estimated that it will save about $90 million annually.

Cigarette Butt Bricks

As the name implies its a brick made of cigarette butts. Cigarette butts contribute to 1.2 million tons of waste every year. Cigarette butts have poor biodegradability, and it can take a few years for them to interrupt down. During this process, heavy metals such as arsenic, chromium, nickel, and cadmium, which have been trapped in the filters, leach into the soil and waterways.

According to new research, if 2.5 percent of the world’s annual brick production assimilated 1 percent butt content, it might be possible to completely offset annual worldwide cigarette production. As the amount of butt content increased within the bricks, they became cheaper. It helps to create a lighter and more efficient brick.

Findings and Observation

Students, researchers, and scientists at top universities and labs around the world are responsible for the access we have to build materials that were hitherto undreamt of. Also, it becomes clear that many things are already changing in the sector concerning the materials used in construction. Combining the traditional building materials with a modern approach, then a more cost and energy-efficient building process will emerge soon.