As we know the technology developed, the construction methods also got evolved and new methods got introduced. Lightweight steel is a good replacement in traditional construction materials. Nowadays the lightweight steel widely uses in building construction both high rise and residential.

The adoption of steel instead of brick and concrete is mainly because of the speed in construction, good sustainability and can be re-used and recycled. In the housing sector, pre-fabricated panelled light steel frames are transported to the sites and assembled using different methods of steel connection.

Lightweight Steel Frames

Lightweight steel frames are produced by cold rolling of galvanized strip steel and they are generally based on the C or Z shaped steel section. Being it is galvanized these are corrosion resistant and relatively thin, commonly 1.0 to 4.0 mm thick in size. Galvanized steel has the yield strength of 280 to 350 N/mm2

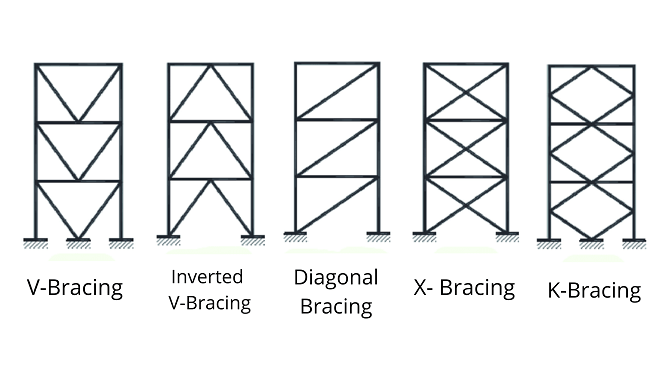

The cold-formed steels are now widely used in building construction such as commercial, industrial and other small scale buildings. It also gained great recognition in the residential building sector because of the ease of handling and speed in construction. One of the main specialities of the light steel members is that they can reduce the earthquake lateral loads/force. The members have a high load-bearing capacity. For stability of the frames integral bracings, X-bracing and diaphragm action principals are followed.

Method of Construction of Steel Structures

Stick-built construction:

In these method different elements of light steel frames taken to the sites and assembled to form a column, beam, walls etc. and attached each other via suitable connections. The elements are given to the sites in required cut length and pre-punched holes but for connections, drilling has to be made manually. This method often used in high rise building, also sometimes in small projects too. One of the main advantages of this method is modification can easily be done.

Panel construction:

In this method, different sections for the buildings such as wall panels, floor elements, and roofs truss are pre-fabricated and assembled it in the site. Construction is much faster and great accuracy will be achieved due to factory production. Desired connections are given manually in the sites to get assembled.

Modular construction:

In modular construction, the units are totally pre-fabricated including finishes and assembled in site. Each unit is stacked on each other side by side as per the design and connected each other. This method is very cost-effective if the production or construction of the same basic units in large scale, which saves time and manpower.

Platform and Balloon Construction:

In platform construction, walls and floor are not continuous because these members assembled subsequently one level only. So the load is transferred wall to floor joist to the wall below happening here.

In balloon constructions, walls are large and continuous over more than one storey. These panels are temporarily braced whilst the floor is installed. The main advantages of this method are the load from the wall directly goes to the bottom. In both methods, finishing is done on-site.

Types of Connections in Steel Structures

There are different types of connections are used in Light steel connections. Some of them are,

1. Welding connection: Two types of welding methods are used, MIG and Spot welding. Special care should give to light steel because of its very thin structure.

2. Bolted connections: Bolts are a common connecting choice in light steel structures because of its ease of handling. Also, the bolts have a good shear capacity.

3. Screw connections: Self-drilling and self-tapping screws are commonly used in connecting light steel elements. Also used to attach finishing materials to light steel frames.

4. Riveted connections: Two types of riveted connections are used, Blind rivets which are fitted into pre-drilled holes and have good pull out resistance. The other type is self-piercing which do not require pre-drilled holes. Hydraulic tools are required to fix screws.

5. Power actuated fasteners: These are used to connect the light steel members to concrete or masonry or other thick steel sections.

Fire resistance and Acoustic performance of Steel Structures

Cold form steel is non- combustible and not lead fire to spread. But the rise in temperature causes loss in structural load-bearing capacity of the light steel. The modulus of elasticity decreases with increase in temperature. So suitable fire insulating materials should provide in walls, floor etc.

Due to the presence of cavities and layers of material in light steel frames, it can achieve good acoustic insulation. The layers of double-wall oriented construction make the acoustic insulation rather than placing heavy components. Also, we can place insulating materials in between walls to improve noise insulation.

Advantages of Steel Structures

- Speed of construction increases

- Wastage of materials is less

- Earthquake resistant

- High-quality control and accuracy can achieve

- Light steel materials are more reliable and can recycle.

- Foundation requirements are less compared to other traditional construction methods.

- Modification and extension can do easily.

Disadvantages of Steel Structures

- Less flexibility in Design

- High thermal conduction

- Buckling issues arises when the length of steel elements increases

- Frequent maintenance required.

Light steel frames now widely using in housing structures and other small scale building constructions. Being steel is used it is very reliable, can reuse and also recycle and that makes the wastage reduction in a considerable amount. Light steel residential buildings are very good innovative and also cost-effective in different ways. This method of construction is useful in the urban sector and expand the possibilities is various construction industries.