Soil stabilization is the process of modification of engineering characteristics of soil such as strength parameters and that increases the bearing capacity of the soil.

It is mostly done if the subgrade soil is not suitable to carry the structural loads. Soil stabilization increases the shear strength of the soil and also decreases the permeability and compressibility of the soil mass.

The simplest soil stabilization process is soil compaction and drainage.

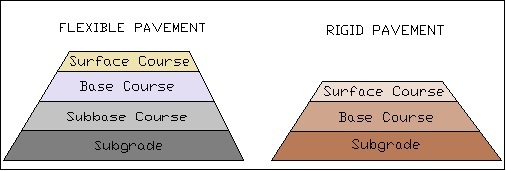

For the pavements works the soil stabilization is very important. The pavement design always focuses on the shear strength capacity, which should be enough to resist the shear forces and capable of avoiding the deflection of layers due to fatigue. These qualities of soil can be increased by the soil stabilization.

Methods of soil stabilization

Soil stabilization can be achieved by following methods,

Mechanical stabilization:

This is the process of attaining the soil stabilization by changing its gradation through compacting the soil using mechanical energy. Rollers, vibrators, earth rammers are commonly used equipment for this technique.

Compaction of the soil clears the entrapped air and pores in the soil, also decrease the permeability. Sometimes mixing of two grades of soil to obtain a composite soil can achieve desired properties. Soil filling and backfill, soil reinforcement are the other two methods to stabilize the soil in slope areas.

Stabilization using Admixtures:

This is also known as the additive method. Chemical additives are added to the soil to meet the desired stabilizing property. These admixtures are bio-degradable, environmental friendly and non-toxic material. Most commonly used are cement, lime, fly ash, blast furnace slag.

Cement: Cement is the most commonly used soil stabilizer in pavement construction. It can give high compressive strength via bond together the soil particles. The hydration of the cement causes the increase of bearing capacity and shear strength of the soil.

Lime: Using lime as a stabilizer is more economic. The cation exchange capacity due to the pozzolanic reaction brings more strength. While adding lime to the clay it will flocculate and the particles changes to needle-like interlocking structures. When lime added to the clay the water content gets reduced by heat generated due to the reaction of lime and water, also lime brings down the density of soil and increase the plastic limit.

Fly ash: Fly ash is the byproduct of coal-fired electric power generation facilities. It has little Cementation property compared to cement and lime. But in the presence of activators, it can possess cementation characteristics and improve soil stability. The drawback of this method is the soil should have less moisture content.

Blast furnace slag: These are the byproduct of pig iron production. It is not the cementitious compound itself but adding lime or alkaline materials leads to develop the hydraulic property.

There are also some other admixtures and methods used, and some of them are,

- Bituminous stabilization: The controlled amount of Bitumen is added to existing soil.

- Rice Husk ash stabilization: It is a pozzolanic material. It is burnt in controlled temperature the ash thus produced used for soil stabilization

- Thermal Stabilization: Done either heating the soil or cooling it to meet the engineering properties of soil.

- Electric stabilization: it is based on the principle of Electro osmosis. DC current is passed to the clay soil, pore water moves towards the negative electrode. It is not economical.

Selection of Stabilizer

The selection of stabilizer is based on the following factors,

- Type of soil

- Purpose of the stabilized soil layer

- Soil quantity

- Strength requirement

- Environmental conditions

- Cost

Factors affecting the strength of stabilized soil

- Organic matter: The presence of a large amount of organic matter reacts with hydration product and results in low pH value. This will retard the hydration process and affect the stabilization of soil.

- Presence of sulphates and sulphides: Presence of Sulphates and Sulphides retards the stabilization of soil.

- Compaction: Good compaction increases the bearing capacity of the soil and also in cement and lime stabilization the compaction has great importance.

- Moisture content: Moisture content is essential for hydration process and efficient compaction. 20% of its own weight by hydrated cement and 32% of its own weight by quick lime is taken from water content from the surroundings.

- Temperature: Pozzolanic reaction is sensitive to temperature changes. Pozzolanic reaction slowdown in low temperature and leads to low strength of stabilized soil.

Soil stabilization in frost areas

If the soil is stabilized with cement or lime, the strength will increase with curing time i.e. the stabilized layer need to be constructed before the freezing cycle starts. Chemical reactions and strength gain do not occur rapidly at a lower temperature.

In frost areas stabilized soil is used only in a layer or layers comprising one of the upper elements of the pavement system and directly beneath the pavement’s surfacing layer.

Treatment with a low degree of chemical stabilization is done in frost areas because weakly cemented material has less capacity to endure repeated freezing and thawing than firmly cemented material. So special consideration should be given for the stabilization of soil in frost areas.

As on the present-day advanced technology introducing verities of methods of soil stabilization and chemicals for it. It is very important to improve the durability, strength and computability of soil for airfields, buildings and pavement construction. Also, other methods like injection and spray techniques have to be explored more in soil stabilization in an economical way. It is essential to explore more methods and techniques for better ways of soil stabilization.

Also Read: Soil Reinforcement