Railway Sleepers are the transverse members that are laid to support the rails.

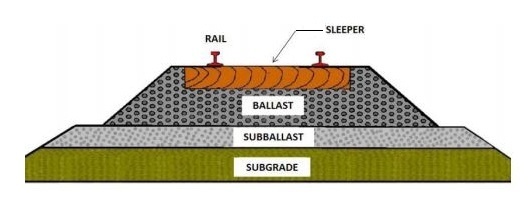

The Typical components of railway tracks are:

- Rails,

- Sleepers (or ties),

- Fasteners,

- Ballast (or slab track),

- Subgrade

The Function of Sleepers in Railway:

- Sleepers hold the rails in proper gauge by fixing them in position.

- It transfers the loads received from the track to the ballast.

- Provide firm and even support

- It provides an elastic medium between the rails and the ballast

- It ensures the stability of the permanent way as a whole.

Requirements of Railway Sleepers:

- The initial and maintenance cost of railway sleepers should be low

- Moderate weight i.e. should be easy to handle

- Sufficient bearing area

- Track circuiting should be possible

- Able to resist shock and vibrations

- Fixing and removing of fasteners should be easy.

- Easy maintenance and gauge adjustments.

Sleeper Density and Spacing of Sleepers

Sleeper Density in the number of sleepers provided per rail length on a track.

It is denoted by (M + x) where M is the length of rail in meters. If the sleeper density is M+ 7 on any route and the length of the rail is 13 m, it means that 13 + 7 = 20 sleepers will be used per rail length of the track on that route.

The number of sleepers in a track can also be specified by the number of sleepers per kilometre of the track.

The value for sleeper density for India is 18, whereas, in the USA, the Value of Sleeper Density is 23-25.

Types of Railway Sleepers

The sleepers can be classified into five main categories, generally depending upon the materials of construction:

- Wooden sleepers

- Steel sleepers

- Cast Iron Sleepers

- R.C.C sleepers

- Prestressed Concrete Sleepers

Wooden Sleepers

Wooden sleepers are made of wooden elements, especially timber. In India, Sal, Teak, Deodar are the most common types of timber used for the manufacture of wooden sleepers. This type of Sleepers is regarded as the best, as they satisfy all the requirements of a good sleeper, but their longevity greatly depends upon the sleepers ability to resist wear, tear and attack from white ants. Wooden sleepers can be manufactured in various length depending upon the gauge length and the type of length.

Advantages of Wooden Sleepers

- Easy availability of timbers.

- Wooden sleepers are suitable for all types of ballast

- They provide less noisy tracks

- Wooden sleepers absorb shocks and vibration, and this ensures a more convenient journey to the passengers than any other Sleepers.

- These sleepers are best suitable for track circuiting.

Disadvantages of Wooden Sleepers

- They are less durable as compared to other types of Sleepers

- Maintainance cost is best suited for track circuiting

- These types of Sleepers are subjected to wear, tear and decay.

Steel Sleepers:

These sleepers are constructed with steel elements, which are generally manufactured using steel troughs made of 6 mm thick steel sheets. An inward slope of 1in 20 on either side is provided to achieve required tilt of rails, at the time of pressing the sleepers. The standard length of these types of Sleepers is 2680 mm.

Steel sleepers are generally of two types—

- Key type steel sleepers: lugs and jaws are pressed in this type of sleepers, and keys are used for holding out the rails.

- Clip & Bolt type steel sleepers: Clip and bolts are used for holding out the rails in this type of Sleepers.

Advantages of Steel Sleepers:

- These sleepers are light in weight and requires less fastenings.

- The gauges can be easily maintained and adjusted

- Their scrap value more than the wooden sleepers

- The life of steel sleepers is more than wooden sleepers.

Disadvantages of Wooden Sleepers:

- The initial cost of these sleepers is more than wooden sleepers.

- Steel sleepers are liable to corrosion

- They are not suitable for all types of ballast.

Cast Iron Sleepers:

These sleepers are made of cast iron. Cast iron sleepers have been extensively used in India as compared to the other countries.

Cast iron sleepers can be widely classified into following types—

- Pot or Bowl Sleepers: Pot sleepers consists of two bowls placed under each rail and connected with a tie bar. On top of each pot, keys are provided to hold the rails in a proper position. Also, the inward slope of the rail seat provided is 1in 20.

- Plate Sleepers: Plate sleepers consists of two rectangular plates. These plates are held in position and direction, using a tie bar.

- Box Sleepers: In this type of sleepers, A box is provided at the top of each plate, having similarities with plate sleepers. These sleepers are in use these days.

- CST-9 Sleepers: It is a combination of Plate, Box, and Pot sleepers. CST-9 Sleepers are most satisfactory than other C.I sleepers and had been extensively used in Indian Railways.

- Duplex Sleepers: These sleepers are used in Conjunction with CST-9 Sleepers. These sleepers are used at rail joints to prevent Cantilever action between two supports of CST-9 Sleepers.

Advantages of Cast Iron Sleepers:

- The maintenance of Cast Iron sleepers are low

- The Cast Iron sleepers are more durable

- The life of C.I sleepers is more

- The gauge can be easily maintained and adjusted using these sleepers.

Disadvantages of Cast Iron Sleepers:

- These sleepers are liable to break

- C.I. sleepers are not suitable for track circuiting

- These sleepers are not suitable for all types of ballast

RCC Sleepers:

As the name indicates, the RCC sleepers are cast using Reinforced Concrete. There is a wide range of advantages of using these types of Sleepers.

There are generally two types of RCC sleepers—

- Thorough Type, and

- Block and Tie type

Advantages of RCC Sleepers:

- Concrete sleepers have a long service life, generally 40 to 60 years.

- They are free from the attack of insects, decay etc.

- They require less fitting and fastenings

- Track circuiting can be executed by using these types of sleepers.

Disadvantages of RCC Sleepers:

- The scrap value for this type of sleepers are Nil

- The renewal of track laid with these sleepers is difficult.

- They are liable to crack due to creep and shrinkage.

Prestressed Concrete Sleepers:

These are the types of sleepers which are extensively used nowadays in Indian Railways. These Sleepers have a high initial cost, but the cost of maintenance and operation is very low. High tension steel wires are used.

Advantages of Prestressed Concrete Sleepers:

- As high tensile wires used and the concrete is Prestressed, they are less liable to cracking.

- They are very strong in resisting tension and do not creep under stress.

- They are very cheap in the long run due to their long life.

Disadvantages of Prestressed Concrete Sleepers:

- These sleepers are heavily damaged in case of derailment or accident of trains.

- The scrap value is zero in these types of Sleepers.

Comparison of different types of Sleepers

| Characteristics | Wooden Sleeper | Steel Sleepers | Cast Iron Sleepers | Concrete Sleepers |

|---|---|---|---|---|

| Service life (years) | 12-15 | 40-50 | 40-50 | 50-60 |

| Handling | Manual handling; no damage to sleeper while handling | Manual handling; no damage to sleeper while handling | Manual handling; liable to break by rough handling | No manual handling; gets damaged by rough handling |

| Type of maintenance | Manual or mechanized | Manual or Mechanized | Manual | Mechanized only |

| Cost of maintenance | High | Medium | Medium | Low |

| Gauge adjustment | Difficult | Easy | Easy | Not required |

| Track circuiting | Best | Difficult; insulating pads are necessary | Difficult; insulating pads are necessary | Easy |

| Damage by white ants and corrosion | Can be damaged by white ants | No damage by white ants but corrosion is possible | Can be damaged by corrosion | No damage by white ants or corrosion |

| Creep | Excessive | Less | Less | Minimum |

| Scrap value | Low | Higher than wooden | High | None |

These are the types of railway sleepers. They all have their own advantages and disadvantages, which may be useful for track laying work in different geographical locations, and depending upon the length of the gauge used for that track in the railway project.

Also Read: Types of Building Materials

dear sir,

I need 3000 pcs of old concrete sleepers.drawing no T-8527 and T-2496. We only need the wire inside it.So we only need delivery near your location.Delivery will be to us anywhere in India. And we can also do it at your place if it suits you. We want to get delivery within a month.

Thank You for This Amazing Content

Kumta